On April 11, 2022, MIT announced five multiyear flagship projects in the first-ever Climate Grand Challenges, a new initiative to tackle complex climate problems and deliver breakthrough solutions to the world as quickly as possible.

One of the biggest leaps that humankind could take to drastically lower greenhouse gas emissions globally would be the complete decarbonization of industry.

A major problem is that industrial manufacturers, whose success depends on reliable, cost-efficient, and large-scale production methods, are too heavily invested in processes that have historically been powered by fossil fuels to quickly switch to new alternatives.

This would be a new approach to decarbonization of industrial materials production that relies on largely unexplored but cleaner electrochemical processes.

Their plan: to create an innovation hub on campus that would bring together MIT researchers individually investigating decarbonization of steel, cement, ammonia, and ethylene under one roof, combining research equipment and directly collaborating on new methods to produce these four key materials.

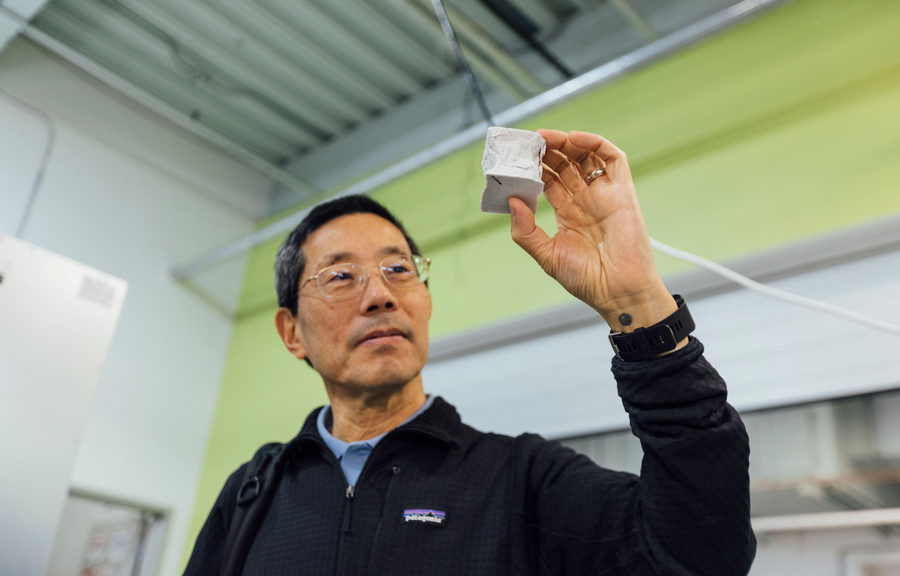

Many researchers across MIT have already signed on to join the effort, including Antoine Allanore, associate professor of metallurgy, who specializes in the development of sustainable materials and manufacturing processes, and Elsa Olivetti, the Esther and Harold E.

Selected from a field of more than 100 proposals, their Center for Electrification and Decarbonization of Industry will be the first such institute worldwide dedicated to testing and scaling the most innovative and promising technologies in sustainable chemicals and materials.

To achieve CEDI’s ambitious goals, a physical location is key, staffed with permanent faculty, as well as undergraduates, graduate students, and postdocs.

Chiang’s background in electrochemistry showed him how the efficiency of cement production could benefit from adopting clean electricity sources, and Yildiz’s work on ethylene, the source of plastic and one of industry’s most valued chemicals, has revealed overlooked cost benefits to switching to electrochemical processes with less expensive starting materials.

The impact of large-scale industry adoption of clean energy sources in these four key areas that CEDI plans to target first would be profound, as these sectors are currently responsible for 7.5 billion tons of emissions annually.

Beyond considering how new solutions will impact industry’s bottom line, CEDI will also investigate unique synergies that could arise from the electrification of industry, like processes that would create new byproducts that could be the feedstock to other industry processes, reducing waste and increasing efficiencies in the larger system.